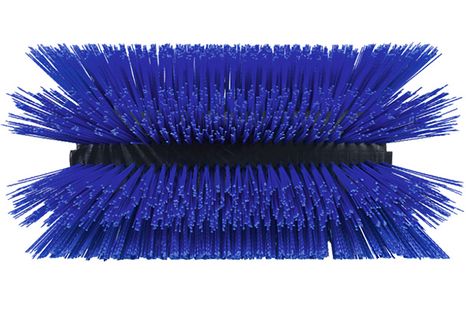

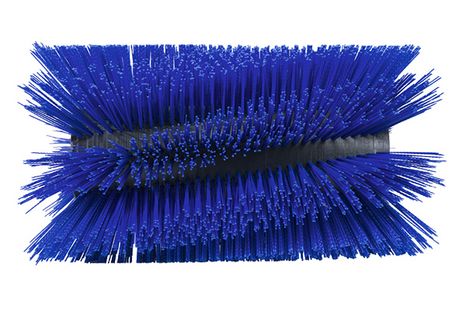

Sweeping rollers – for any application and for all common front-mounted sweepers and self-collecting machines

The ideal sweeping roller for any machine. This is what Weber Bürstensysteme, one of the leading suppliers of sweeping rollers for road and pavement cleaning stands for. Weber develops not only standard systems, but also special solutions tailored exactly to the vehicles and requirements.

Effective

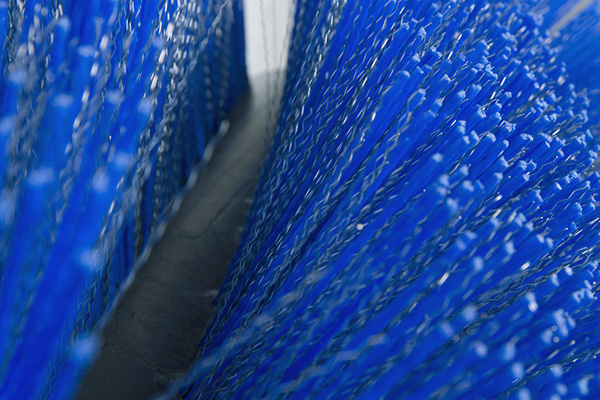

- Effective transportation of dirt by spiral-shaped bristle arrangement

- Smooth operation

Universal

- For any kind of soiling, from respirable dust to building site rubble

- High bristle density

Powerful

- Easily removes persistent and crusted soiling

- ldeally suited for building site cleaning

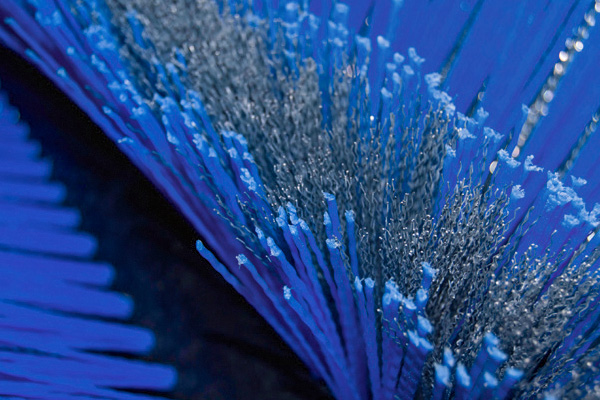

- A mixture of crimped wire and plastic bristles

Aggressive

- High bristle density of high quality plastic combined with robust crimped wire

- Provides optimum cleaning performance, e.g. in case of coarse dirt (split etc.)

Persistent

- High performance nylon bristles

- Extended operating life

- Low wear

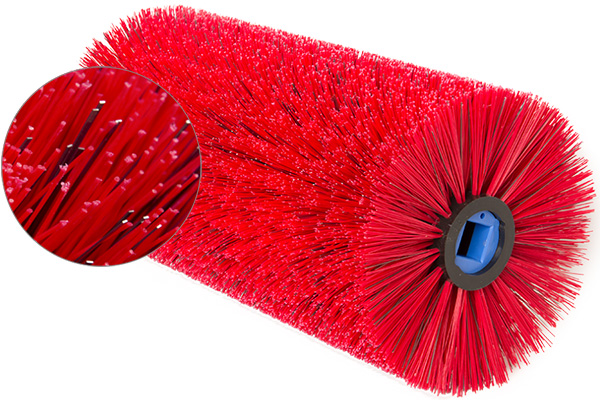

Bristle types

Any sweeping roller is only as good as its bristles. Sweeping efficiency and service life are influenced by the bristle arrangement, the material mixture, as well as by the bristle strength and density. Premium quality raw materials are the basis for the quality and efficiency of our sweeping rollers. To ensure optimum cleaning efficiency, we adapt all components to each machine type and each application.

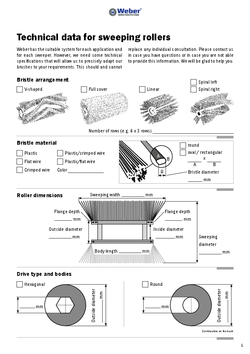

Technical data for sweeping rollers

Weber has the suitable system for each application and for each sweeper. However, we need some technical specifications that will allow us to precisely adapt our brushes to your requirements.

This should and cannot replace any individual consultation. Please contact us in case you have questions or in case you are not able to provide this information. We will be glad to help you.

Please download the data sheet and return this to us by fax or mail after completing it.