Concrete block brushes

Weber is one of the leading suppliers of special brushes for concrete block production.

Introduced in the early 1970s, Weber’s original strip brush has set the standard in terms of quality and performance. These standards are still valid today. We have been working with leading manufacturers of concrete block producers and concrete block production machine manufacturers for more than 40 years.

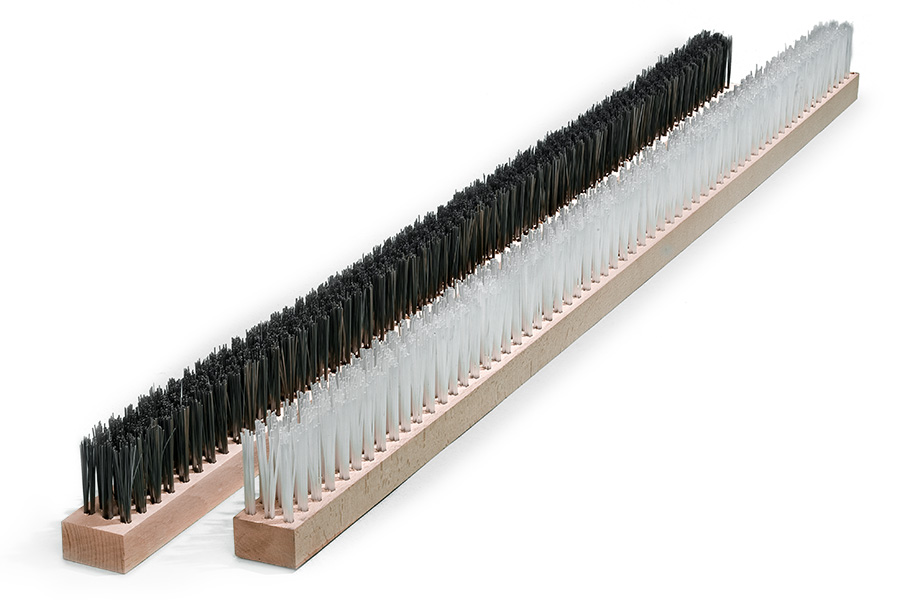

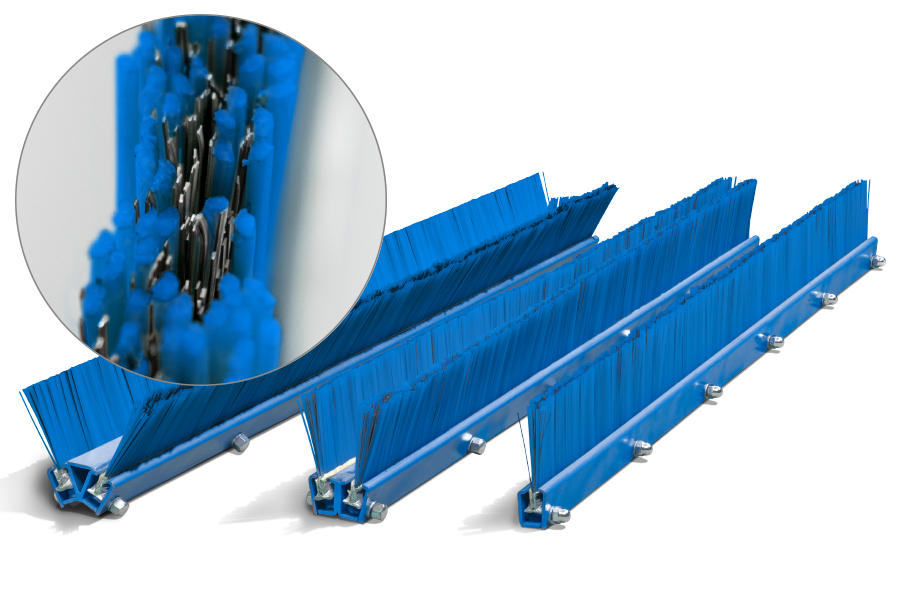

Feed drawer brushes KingCon® 2.0

Plastic on the outside, metal wire on the inside, tightly connected to a galvanized steel profile back. To this day, a unique system from Weber. The bristle density is higher than in any other comparable brush. The new generation with optimised bristle anchoring is even more durable than its predecessors!

Weber feed drawer brushes have been designed to withstand the extreme stress occurring during the production process. Our special material mixture, the comparatively high bristle density, the improved fixation as well as the number of bristle lines ensure a consistently high quality of the concrete blocks and a thorough cleaning of the stamp. We offer three different types of brush holders which are attached to the feed drawer.

The unique Weber principle

Powerful double action: The flat wires on the inside are protected and stabilized from the outside by abrasion-resistant nylon bristles. The result: effective shoe cleaning and extended service life.

- Outer bristles: nylon 2 x 3 mm blue / poly 1.2 mm red

- Inner bristles: metal wire 1.1 x 0.25 mm

- Bristle length: 115 and 85 mm (others on request)

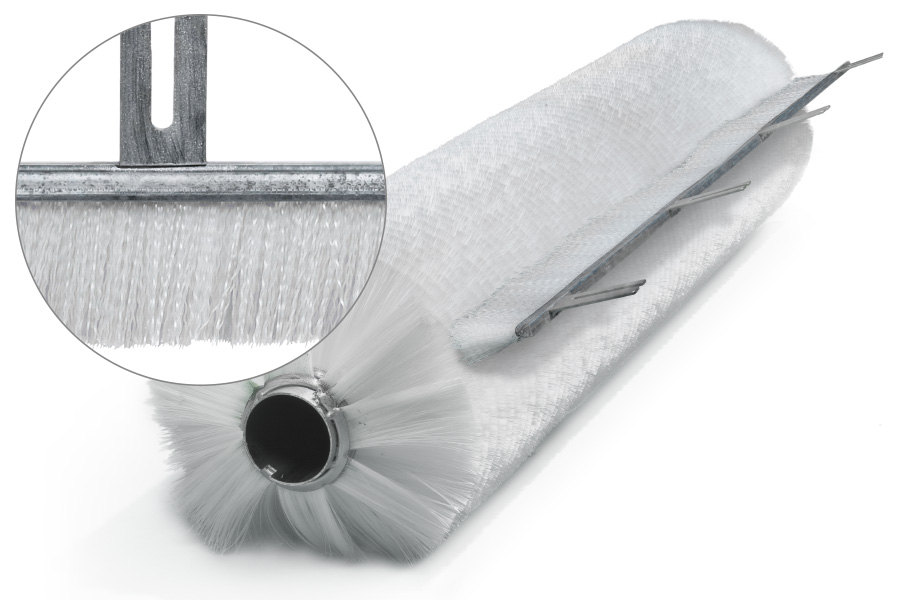

Spiral brushes

Rotary brushes for green products

The spiral-shaped bristle arrangement produces a lateral sweeping movement so that burrs on the side or on the back can be removed more easily. Thanks to the loose spiral shape, this brush can be set deeper than conventional brushes. The effect: the bristles are able to penetrate the gaps between the stones deeper without causing any damage.

Technical specifications:

- Pipe diameter: 45, 55, 65, 80, and 103 mm

- Sweep diameter: 150-500 mm

- Length: up to 2.500 mm

- Spiral slope: 20 mm (< 100 r.p.m.), up to 50 mm (> 100 r.p.m.) and fully covered

- Material: premium-quality nylon bristles or standard qualities such as polypropylene

Sweep-out brushes are used to effectively clean bristle heads and interspaces in spiral brushes to prevent mud points or encrustations. The length of the brush carrier and of the bristles, as well as the number of retaining brackets, can be individually adapted to the spiral brush.

Mould brushes

Custom-fit, mould brushes for any curbstone. Weber offers premium-quality, custom-fit mould brushes for the lateral cleaning of upstanding, round, flat, or flush curbs, including both standard and special geometries.

- For all standard curb geometries

- Individual shapes and versions available

- Variable material mixture: nylon, flat wire, or mixture

- Particularly shock-resistant plastic body

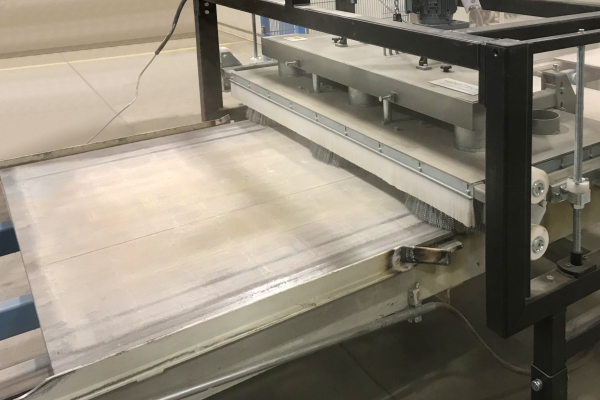

Based on five overlapping brushes which cover any position of the plate surface, our Crust Cracker® offers the best cleaning performance of inline systems. Depending on the conditions on site, and on the condition of the boards, the brushes can be equipped with the best suitable bristle material: from highly aggressive nylon to slightly abrasive polypropylene.

Encrusted concrete residuals, dirt and rust can thus be removed promptly, effectively preventing new accumulations.

Crust Cracker® is an autonomous, automatically controlled system that can be integrated in all existing production lines.

As an addition to the Crust Cracker® we recommend the special release agents for production boards from Rhein-Chemotechnik GmbH.

tectol CoatRelease and tectol CoatRelease 2 are environmentally friendly special release agents for production boards in concrete products coating processes. The application of tectol CoatRelease and tectol CoatRelease 2 before coating concrete products significantly reduces sticking of coating material to the production boards.

- effective release action

- easier removel of coating material overspray

- to be applied easily

- economical in use

- readily biodegradable

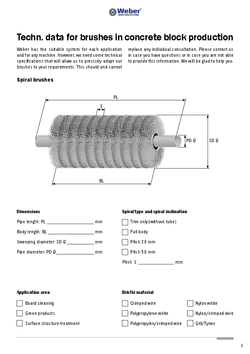

Technical specifications for spiral brushes and feed drawer brushes with steel body or wooden body

A perfect fit of the brushes is vital for effective cleaning. However, we need some technical specifications that will allow us to precisely adapt our brushes to your requirements.

This should and cannot replace any individual consultation. Please contact us in case you have questions or in case you are not able to provide this information. We will be glad to help you.

Please download the data sheet and return this to us by fax or mail after completing it.